|

||||

|

Waterwheel | |||

|

|

|

||

|

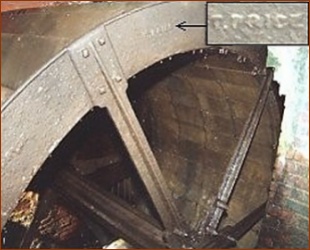

In a watermill, the waterwheel is the primary source

of power to operate the mill. Without a wheel, and an adequate supply of

water, a watermill cannot work. Although the mill pond still survives,

New Hall Mill lost the water supply The wheel is an external overshot wheel, 11ft (3.35m)

in diameter and 6ft (1.83m) wide, fitted with 36 buckets supported by

two sets of six cast iron arms on an 8" iron shaft. The name

"T. Price" is cast into the shrouds but it is believed the

wheel was made by George Turton of Kidderminster, most likely in the

1870's or 1880's. The bucket risers and sole boards were originally

wooden but with the last miller rarely recycling the water in the

collecting tank back to the mill pond, those at the bottom of the wheel

remained in the water leading to them becoming waterlogged and rotten

and |

||||