|

|||

|

Gear Wheel with Broken Wooden Teeth | ||

|

|

||

|

What happens

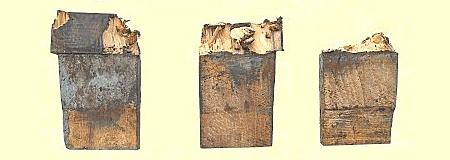

when a rotating cast iron bevel gear meets a stationary stone nut with wooden teeth? A horrible 'crunching' sound and a row of broken teeth! The teeth are in two parts, an upper and a lower, and as the two gearwheels came into contact, many lower parts were broken. The remains of one upper and two lower are shown on the left after removal from the stone nut. |

||

| As it was impossible to remove the stone nut from the stone spindle without lifting the bed stone, repairs had to carried out while it remained on the stone spindle. After raising it to a workable position, the damaged teeth were removed either by driving them out from the iron casting or by drilling out the remains to clear the socket. It was fortunate that some suitable teeth were available in a spare stone nut that could be transferred as replacement teeth. The upper right picture shows the repaired stone nut with the replacement teeth awaiting final trimming before being carefully lowered down to engage the teeth with the stationary bevel gear for testing. | |||